Products

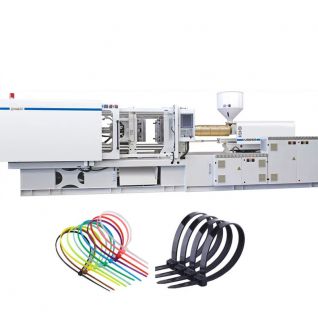

hybrid servo plastic injection molding equipment

Our plastic injection molding equipment have different models according to different designs or customers' samples.

Port:

Shanghai Port, Ningbo port, Shenzhen port,Tianjin port

Lead Time:

Hybrid servo plastic injection molding equipment

hybrid servo machine main features

The servo motor drives screw bal so to achieve machine pre-plasticizing and injection movement

Pre-plasticizing, backpressure, injection and holding pressure has realized fuldosed-oop numerical control, making injection repeat precision reach up to 0.01mm

The camping structure consists of servo motor drives high precision fixed pump /hydraulic transmission

Overall machine movement is timely controlled and accurately run according toproducts processing technology

Servo system as well as wel-matched high response controller has fully appliedto machine cycle

Hybrid servo plastic injection molding equipment has been a popular alterative for full electric machine, which isapplicable to ultra-thin-wall and high precision products processing

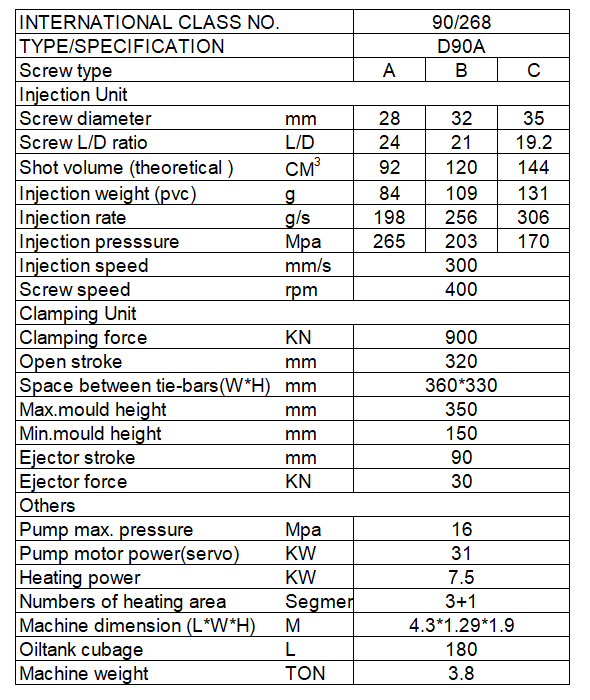

Product Specifications

FAQ:

Q1: What is a hybrid electric-servo injection molding machine?

A: It combines electric servo motors with hydraulic systems to optimize energy efficiency and precision in molding processes.

Q2: How does a hybrid machine reduce energy consumption compared to traditional hydraulic machines?

A: It uses servo motors for precise control, minimizing idle energy waste and only activating hydraulic pumps when needed.

Q3: What are the key advantages of servo-driven systems in injection molding?

A: Faster response times, higher repeatability, reduced noise, and lower energy use.

Q4: What industries benefit most from hybrid electric-servo machines?

A: Automotive, medical devices, electronics, and precision engineering sectors requiring high-quality, complex parts.

Q5: How does the hybrid system improve mold cycle times?

A: Servo motors enable rapid acceleration/deceleration and precise positioning, shortening cycle phases.